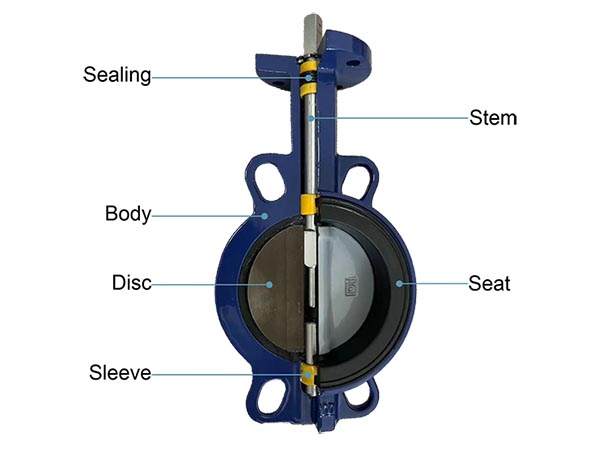

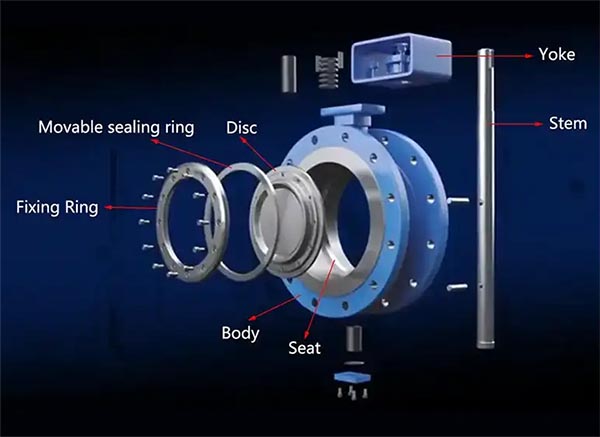

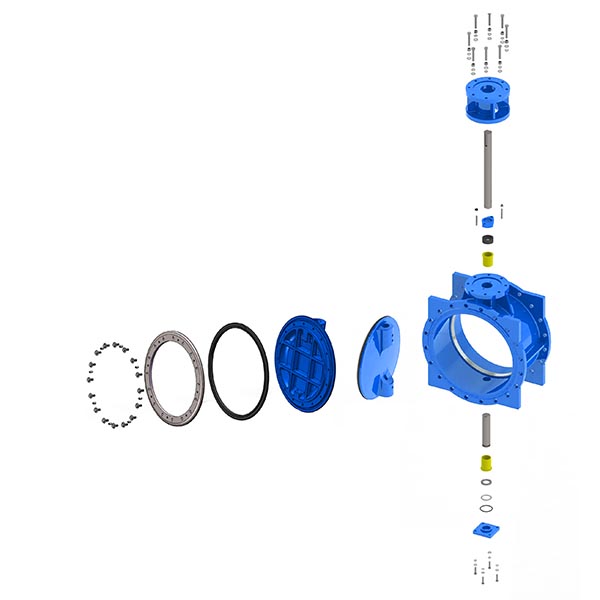

Kursiga waalka ee waalka balanbaalistu waa qayb muhiim ah oo shaabad ah oo ku jirta waalka balanbaalistu. Shaqadeeda ugu weyn waa inay la xiriirto saxanka balanbaalistu (saxanka waalka) oo ay sameyso dusha shaabad marka waalka la xiro si looga hortago daadashada dhexdhexaadka ah. Gaar ahaan,kursiga waalka balanbaalistuwaxaa lagu rakibi karaa derbiga gudaha ee jirka waalka ama loogu talagalay in lagu daro saxanka balanbaalisyada, iyadoo lagu tiirsanaanayo agabkeeda iyo qaab-dhismeedkeeda si loo gaaro saameyn shaabad wanaagsan.

1. Hordhac Kala-soocidda Kursiga ee waalka balanbaalis

1. 1 Kala soocidda agabka

A. Kursiga waalka jilicsan ee dabacsan

Badanaa waxaa loola jeedaa agabyada sida cinjirka, silikoon, polytetrafluoroethylene (PTFE).

Faa'iidooyinka: waxqabadka shaabad wanaagsan, jawaab degdeg ah, ku habboon heerkulka hooseeya, cadaadiska hooseeya iyo warbaahinta daxalka yar (marka laga reebo PTFE).

Qasaarooyinka: iska caabin la'aanta xirashada, cimriga adeegga waxaa xaddidaya gabowga walxaha.

B. Kursiga waalka birta ah

Laga sameeyay bir aan miridh lahayn, bir kaarboon ama walxo kale oo bir ah.

Faa'iidooyinka: iska caabin heerkul sare, iska caabin cadaadis sare, iska caabin adag oo xirasho, oo ku habboon xaaladaha shaqada ee adag.

Qasaarooyinka: shuruudaha sare ee shaabadaynta birta-ilaa-birta, saxnaanta habaynta adag iyo shuruudaha rakibidda.

C. Kursiga waalka ee isku dhafan

Waxay isku daraysaa faa'iidooyinka birta iyo walxaha jilicsan, iyadoo badanaa qaab-dhismeedka birta ku dabooleysa walxo laastikada ah sida graphite.

Kaliya ma hubin karto waxqabadka shaabad wanaagsan, laakiin sidoo kale waxay hagaajin kartaa iska caabbinta xirashada iyo cimriga adeegga.

1.2. Kala soocidda qaab dhismeed ahaan

A. Kursiga dambe ee adag

Kursiga waalka iyo dhabarka ayaa si isku mid ah loo sameeyay, oo leh qaab-dhismeed fudud, dusha sare ee shaabadaysanina si adag ayay ugu habboon tahay jirka waalka.

Khasaaraha arrintankursiga waalka ee dhabarka adagwaa marka kursiga waalka la xidho ama la duugo, waalka balanbaalis oo dhan waa in la kala furfuraa si loogu beddelo.

B. Kursiga jilicsan ee la saari karo

Thekursiga waalka jilicsanwaxay qaadataa naqshad dovetail ah waxaana la kala furfuri karaa oo si gooni ah loo beddeli karaa.

Faa'iidada ayaa ah inay fududahay in la ilaaliyo oo la dheereeyo cimriga adeegga ee waalka balanbaalis guud ahaan.

1.3. Sida waafaqsan naqshad gaar ah

A. Waalka balanbaalisyada ee laba-jibbaaran ee aan caadiga ahayn

Saxanka balanbaalistu wuxuu ku socdaa laba dhidib oo aan caadi ahayn marka la xiro si loo yareeyo is-qabsiga taabashada kursiga waalka.

Faa'iidooyinka waa xirashada oo yaraata, cimriga kursiga waalka oo la dheereeyo, iyo waxqabadka shaabadeynta oo la wanaajiyo.

B. Waalka balanbaalisyada ee saddex-geesoodka ah ee aan caadiga ahayn

Naqshad dheeraad ah oo ku salaysan laba-jibbaaran oo aan sinnayn ayaa u suurta gelinaysa saxanka balanbaalisyada iyo kursiga waalka birta inay gaaraan xiriir sax ah oo bir-ilaa-birta ah.

Waxay gaari kartaa saameyn eber ah oo daadasho ah waxayna ku habboon tahay xaaladaha shaqada ee baahida sare leh (sida heerkulka sare iyo warbaahinta cadaadiska sare leh).

Noocyada kala duwan ee agabka kursiga waalka waxay leeyihiin sifooyin jireed iyo kiimiko oo kala duwan waxayna ku habboon yihiin xaalado shaqo oo kala duwan. Maqaalkan, waxaan inta badan ku baraneynaa oo isbarbardhigeynaa noocyada ugu muhiimsan, waxqabadka iyo codsiyada kuraasta waalka laastikada ah.

Kuraasta waalka laastikada ee suuqa laga isticmaalo waxaa ka mid ah NBR, EPDM, VITON (FKM), caag dabiici ah (NR), silicone (Silicone Rubber), polyurethane (PU), caag nitrile hydrogenated (HNBR), HYPALON (CSM), PTFE:

2. Isbarbardhigga Astaamaha Agabka Kursiga ee Waalka

| Alaab | NBR (Nitrile Cinjir) | EPDM (Ethylene Propylene Diene Monomer Rabadhka) | VITON (FKM/Fluorocarbon Rabadh) | NR (Caydh Dabiici ah) | Cinjir silikoon ah | PU (Polyurethane) | HNBR (Rabadhka Nitrile ee Haydarojiin leh) | HYPALON (CSM/Cyber Polyethylene ah oo lagu daray Chlorosulfonated) | PTFE (Polytetrafluoroethylene, Teflon) |

|---|---|---|---|---|---|---|---|---|---|

| Iska caabbinta Saliidda | Aad u fiican | Liita | Aad u fiican (waxay iska caabisaa shidaalka iyo kiimikooyinka) | Liita | Liita | Dhexdhexaad ah | Aad u fiican (wuxuu iska caabiyaa saliidda, shidaalka, iyo saliidaha) | Dhexdhexaad ah | Aad u fiican (iska caabbinta kiimikada ugu fiican) |

| Iska caabinta Kiimikada | Dhexdhexaad, iska caabiya asiidhyada iyo saldhigyada khafiifka ah | Aad u fiican (wuxuu iska caabiyaa asiidhyada, saldhigyada, iyo oksaydhiyeyaasha) | Aad u fiican (wuxuu iska caabiyaa asiidhyada, saldhigyada, dareerayaasha dabiiciga ah) | Dhexdhexaad ah | Aad u fiican (waxay iska caabisaa oksaydhiyeyaasha, ma aha sun) | Dhexdhexaad ah | Wanaagsan (wuxuu iska caabiyaa asiidhyada iyo saldhigyada khafiifka ah) | Aad u fiican (wuxuu iska caabiyaa asiidhyada, saldhigyada, iyo oksaydhiyeyaasha) | Aad u fiican (waxay ka hortagtaa dhammaan kiimikooyinka) |

| Kala duwanaanshaha Heerkulka (°C) | -30 ~ 100 | -40 ~ 120 (gaaban ilaa 150) | -20 ~ 200 | -50 ~ 70 | -60 ~ 230 | -30 ~ 80 | -40 ~ 150 | -40 ~ 130 | -200 ~ 260 |

| Xidho Iska caabinta | Wanaagsan | Dhexdhexaad ah | Wanaagsan | Aad u fiican (iska caabin xirasho oo heer sare ah) | Dhexdhexaad ah | Aad u fiican (iska caabbinta xirashada ugu fiican) | Aad u fiican | Wanaagsan | Liidata (si fudud ayay u duugowdaa) |

| Iska caabbinta Biyaha | Dhexdhexaad ah | Aad u fiican (ku habboon biyaha kulul iyo uumiga) | Dhexdhexaad ah | Wanaagsan | Aad u fiican (cunto heer sare ah) | Dhexdhexaad ah | Wanaagsan | Aad u fiican | Aad u fiican (biyo la'aan) |

| U adkeysiga Cimilada (UV/Ozone) | Liita (si fudud ayuu u gaboobaa) | Aad u fiican (iska caabbinta cimilada sare) | Wanaagsan | Dhexdhexaad ah | Aad u fiican (iska caabbinta cimilada aadka u daran) | Dhexdhexaad ah | Aad u fiican (iska caabbinta cimilada sare) | Heer sare (iska caabbinta cimilada sare) | Aad u fiican (iska caabbinta UV iyo gabowga) |

| Dabacsanaan | Wanaagsan | Aad u fiican | Dhexdhexaad ah | Aad u fiican | Aad u fiican | Wanaagsan | Aad u fiican | Wanaagsan | Adag (isku dhac yar) |

| Codsiyada ugu Muhiimsan | Shidaal, saliid saliidayn, nidaamyada saliidda haydarooliga, shaabadaha warshadaha | Nidaamyada biyaha iyo dheecaanka, dhuumaha kiimikada, nidaamyada uumiga, qalabka bannaanka | Codsiyada kiimikada heerkulka sare leh, nidaamyada shidaalka, hawada sare, kiimikooyinka batroolka | Macdan qodista, qalabka u adkaysta xirashada, dahaarka farsamada | Cuntada, daawooyinka, shaabadeynta elektaroonigga ah, codsiyada heerkulka sare iyo kan hoose | Shaabad farsamo, qalab u adkaysta xirashada, macdan qodista, nidaamyada haydarooliga | Kiimikooyinka Batroolka, warshadaha baabuurta, shaabadaha saliidda heerkulka sare leh | Warshadaha kiimikada, deegaannada daxalka leh, qalabka bannaanka, shaabad u adkaysta ozone-ka | Kiimikooyin xooggan oo xoqan, daawooyin, shaabad heer cunto ah, shaabad heerkul sare leh |

3. Xaaladaha Shaqada ee Ku Habboon Qalabka Kursiga Valfka

| Alaab | Iska caabbinta Shidaalka/Saliidda | Iska caabbinta Aashitada/Saldhigga | Iska caabinta Heerkulka Sare | Iska caabinta Heerkulka Hoose | Iska caabbinta Biyaha | Xidho Iska caabinta | U adkeysiga Cimilada (Dibadda, Ozone) | Heerka Cuntada |

|---|---|---|---|---|---|---|---|---|

| NBR | ✔ | ❌ | ❌ | ❌ | ❌ | ✔ | ❌ | ❌ |

| EPDM | ❌ | ✔ | ✔ | ✔ | ✔ | ❌ | ✔ | ✔ |

| VITON | ✔ | ✔ | ✔ | ❌ | ❌ | ✔ | ✔ | ❌ |

| NR | ❌ | ❌ | ❌ | ✔ | ✔ | ✔ | ❌ | ❌ |

| Silikoon | ❌ | ✔ | ✔ | ✔ | ✔ | ❌ | ✔ | ✔ |

| PU | ❌ | ❌ | ❌ | ❌ | ❌ | ✔ | ❌ | ❌ |

| HNBR | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ❌ |

| HYPALON | ❌ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ❌ |

| PTFE | ✔ | ✔ | ✔ | ✔ | ✔ | ❌ | ✔ | ✔ |

4. Talooyinka Xulashada Agabka

· Loogu talagalay codsiyada shidaalka, saliidda, ama saliidda haydarooliga → NBR, HNBR, VITON

· Wixii aashito/saldhig iyo iska caabbinta kiimikada→ EPDM, HYPALON, VITON, PTFE

· Wixii iska caabin heerkul sare ah (>150°C)→ VITON, Silikoon, HYPALON, PTFE

· Loogu talagalay codsiyada heerkulka hooseeya (<-40°C)→ NR, Silikoon, PTFE

· Wixii sare u qaadida iyo iska caabbinta xoqidda (macdan qodista, mashiinnada)→ NR, PU, HNBR

· Biyaha la cabbo iyo codsiyada heerka cuntada → EPDM, Silicone, PTFE

· U adkeysiga dibadda iyo ozone-ka → EPDM, HYPALON, Silikoon, PTFE

5. Gunaanad

· NBR (Nitrile Rabadhka): Ugu fiican isticmaalka saliidda ku salaysan sida shidaalka, saliidda haydarooliga, laakiin aan ku habboonayn heerkulka sare iyo asiidhyada/saldhigyada.

· EPDM (Ethylene Propylene Rubber): Ku habboon daaweynta biyaha, kiimikada, iyo nidaamyada uumiga; aad bay u adkaysi badan tahay cimilada laakiin ma aha mid u adkaysi badan saliidda.

· VITON (Fluorocarbon Rabadhka): Aad ugu fiican heerkulka sare, asiidhyada/saldhigyada xooggan, iyo codsiyada shidaalka.

· NR (Rabadhka Dabiiciga ah): Iska caabin sare oo xoqid ah, oo loo isticmaalo macdan qodista iyo mashiinnada laakiin aan u adkaysan kiimikooyinka.

· Kaarboor Silikoon ah: Aad ugu fiican heerkulka sare/hoose, codsiyada cuntada ee badbaadada leh, laakiin ma laha iska caabin xirasho.

· PU (Polyurethane): Ugu fiican u adkeysiga xirashada xad dhaafka ah, oo loo isticmaalo shaabadeynta haydarooliga iyo codsiyada macdanta.

· HNBR (Nitrile-ka Haydarojiinaysan): Ka wanaagsan NBR marka loo eego heerkulka sare iyo isticmaalka, oo loo isticmaalo warshadaha batroolka.

· HYPALON (CSM/Chlorosulfonated Polyethylene Rabadhka): Ugu fiican iska caabbinta aashitada/saldhigga iyo soo-gaadhista cimilada, oo ku habboon shaabadaynta kiimikada iyo ozone-ka.

· PTFE (Polytetrafluoroethylene): Waa kan ugu adkeysiga kiimikada, uguna habboon heerkulka sare, deegaanka daxalka leh, iyo habaynta cuntada.